Understanding a Life Cycle Assessment (LCA) of grinding application

How the choice of abrasive grains makes an impact from cradle to grave.

The grains in abrasive materials, such as sandpaper or grinding wheels, are a key factor in the efficiency and effectiveness of the abrasive. Saint-Gobain Abrasive Grains has been providing premium solutions to the abrasives industry for decades, with proven high performance in the field. Engineered grains can provide faster material removal with lower power consumption during the grinding process, while delivering longer lifetimes than commodity options.

Saint-Gobain has extensive internal application testing capabilities, which has enabled them to conduct testing of different grains. Of particular interest is the performance comparison of Brown Fused Alumina (BFA), a popular commodity abrasive grain, and Targa ceramic alumina grains offered by Saint-Gobain Abrasive Grains.

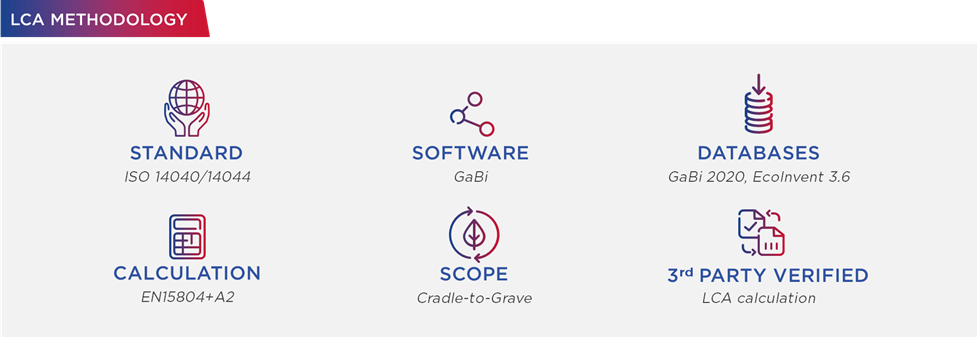

Saint-Gobain Abrasive Grains is committed to providing more information on the environmental impact of their products. In order to take the first step towards this goal, they have conducted a Life Cycle Assessment (LCA) using a representative scenario according to the ISO 14040 and 14044 standards. The insights from this kind of assessment can provide answers to questions about the carbon footprint (e.g. Assessing the global warming potential indicator) of abrasives and which phases of the product life cycle have the highest impact. The results can help identify where development efforts would be most helpful in reducing the environmental footprint of abrasive products.

LIFE CYCLE ASSESSMENT RESULTS

Saint-Gobain Abrasive Grains specializes in manufacturing abrasive grain products for a broad range of abrasive applications. Due to its position in the supply chain, it does not typically manufacture end-use abrasive products. However, a test was developed internally to assess the potential environmental impact of a grinding application using different abrasive grains. This test uses a specially designed abrasive wheel, referred to here as Research & Development (R&D) wheels, that is similar to an end use product. The LCA was conducted on these R&D wheels as a representative scenario, in lieu of a customer product.

The interest in conducting this study is to assess the potential difference (in %) in terms of environmental impact (e.g. CO2eq emission, energy use, etc.) of R&D Grinding wheels made of TARGA or BFA abrasive grains, at all phases from raw material extraction to disposal.This type of life cycle assessment is commonly referred to as “cradle-to-grave" LCA.

LEARN MORE

If you are interested in reading about the details of the study, please contact us for more information! We also invite any of our clients who would like to study results specific to their use case to collaborate with us.