Lapping & Polishing Grains

Performance-Enhancing Shape and Hardness

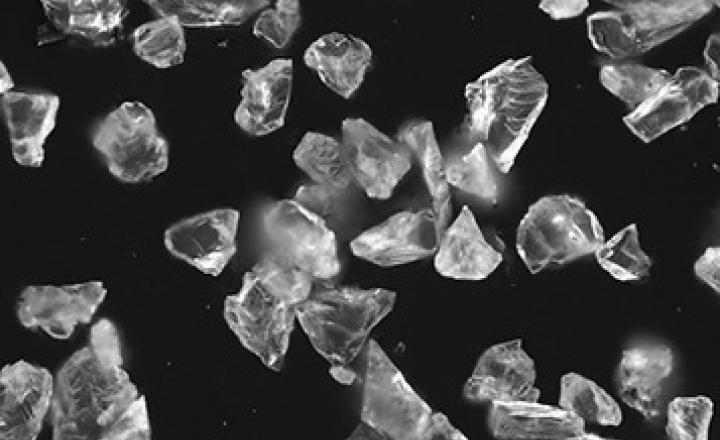

Precision alumina is manufactured from high-quality calcined alumina feed stock. The platey shape and hardness of this abrasive grain allows it to perform well when lapping harder materials. Applications include lapping cast iron, bronze, and steel seals; lapping slide gate valves for flatness and precise surface finish; lapping fuel injector parts; lapping the OD of cylinders and spheres for roundness and surface finish; lapping silicon, gallium arsenide, and other semiconductor materials; and polishing stainless steel flat stock for uniform finish.

Extra Durability and Sharp Cutting Action

Micrograded Alundum® lapping powder is a fused aluminum oxide engineered for precision machining operations on softer materials such as copper, iron, and aluminum. Micrograded Alundum is relatively blocky in shape, which provides extra durability and sharp cutting action. It is sized to tight limits with special attention to coarse grain control. Each batch is lap-tested in Saint-Gobain Abrasive Grains' laboratory to confirm it will not scratch in the actual application. Micrograded Alundum is most commonly used for lapping cast iron seals, piston rings, steel rings, and bronze rings to specified flatness with scratch-free surfaces.

Saint-Gobain Abrasive Grains' cultivates strong, long-lasting relationships with its customers through close collaboration, working side-by-side to develop innovative solutions for their unique challenges.